Wire bonding machines are critical tools in the semiconductor packaging process, and the choice of EFO (Electronic Flame-Off) wand material directly impacts spark stability, service life, and overall bonding quality. Different EFO wand materials vary significantly in electrical conductivity, high-temperature resistance, and oxidation resistance, which, in turn, affect bonding efficiency and production costs. Below is an overview of the characteristics, advantages, disadvantages, and selection points of commonly used materials.

I. Common EFO Wand Materials and their Characteristics

1. Tungsten (W)

Advantages:

Very high melting point (3422°C), providing excellent high-temperature resistance and suitability for high-frequency discharge.

High hardness and good wear resistance, resulting in longer service life.

Good oxidation resistance, making it suitable for high-energy discharge applications (e.g., thick aluminum wire bonding).

Disadvantages:

High brittleness, prone to fracture under mechanical impact.

Moderate electrical conductivity, requiring higher voltage to generate sparks.

2. Molybdenum (Mo)

Advantages:

High melting point (2623°C), with temperature resistance close to tungsten.

Better toughness than tungsten, offering stronger resistance to mechanical shock.

Disadvantages:

Prone to oxidation at high temperatures, requiring use in an inert gas environment.

Slightly higher cost compared to tungsten.

3. Copper (Cu) or Copper Alloys

Advantages:

Excellent electrical conductivity, ensuring stable discharge energy and suitability for precision bonding (e.g., gold wire bonding).

Good ductility, making it less prone to fracture.

Disadvantages:

Low melting point (1083°C), leading to faster wear at high temperatures and shorter service life.

Requires frequent replacement, resulting in higher maintenance costs.

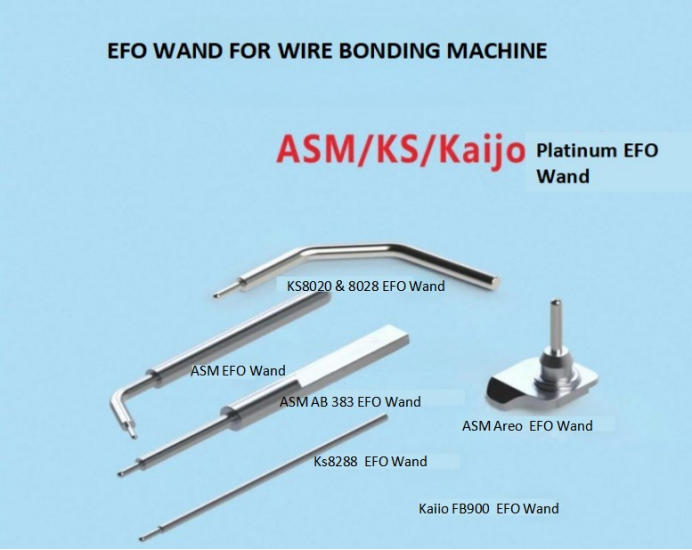

4. Platinum (Pt) or Platinum-Iridium Alloys

Advantages:

Exceptional oxidation resistance, with virtually no material loss and extremely long service life.

Superior spark stability, ideal for high-precision bonding (e.g., semiconductor packaging).

Disadvantages:

Very high cost, limiting its use to special high-end applications.

5. Ceramic-Coated Materials

Advantages:

Ceramic surface coating reduces metal evaporation contamination, improving discharge purity.

Extends the service life of the base material (e.g., tungsten/molybdenum).

Disadvantages:

Performance declines sharply once the coating peels off.

II. Importance of Material Selection

1. Impact on Bonding Quality

Materials with poor conductivity (such as tungsten) may cause unstable spark energy, resulting in weak bonds or uneven ball sizes.

High-melting-point materials (such as tungsten and molybdenum) are suitable for high-current discharge, while copper and platinum are better suited for precision, low-current applications.

2. Maintenance Costs

Tungsten and molybdenum have long service lives but are brittle and prone to breakage.

Copper wears out quickly but is easy and inexpensive to replace.

Platinum is extremely costly but requires little to no maintenance.

Therefore, a balance must be struck between procurement costs and machine downtime.

3. Matching Process Requirements

Thick wire bonding (e.g., aluminum wire): Tungsten or molybdenum are preferred due to their high-temperature resistance and ability to withstand metal spatter.

Precision gold wire bonding: Copper or platinum can be chosen to ensure spark stability.

High-frequency discharge: High-hardness materials (e.g., ceramic-coated tungsten) are recommended to reduce wear.

4. Environmental Adaptability

In oxidative environments, platinum or ceramic-coated materials are more reliable.

In inert gas environments, molybdenum is a suitable choice.

III. Selection Recommendations

1. Evaluate Process Parameters: Select materials based on discharge current, operating frequency, and wire type (gold, aluminum, or copper).

2. Cost-Benefit Analysis: For high-volume production lines, prioritize long-life materials such as platinum or tungsten. For small-batch or flexible production, copper may be a more cost-effective choice.

3. Maintenance Convenience: If replacing the EFO wand is time-consuming, high-stability materials are recommended to reduce downtime and improve overall efficiency.

4. Supplier Technical Support: Some special alloys (e.g., platinum–iridium) require customization. It is essential to ensure a reliable and consistent supply chain.

We are proud to participate in GOACON 2026 in Gujarat, showcasing our Ceramic Femoral Head and Liner...

READ FULLIn copper wire bonding, inert gas is essential to block oxygen from the atmosphere and prevent oxida...

READ FULL