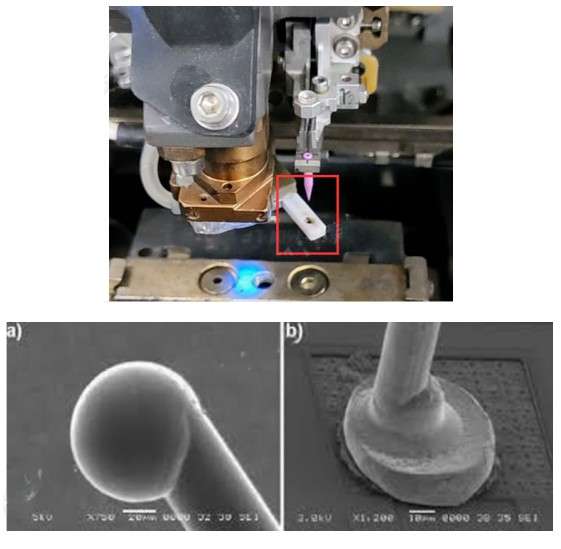

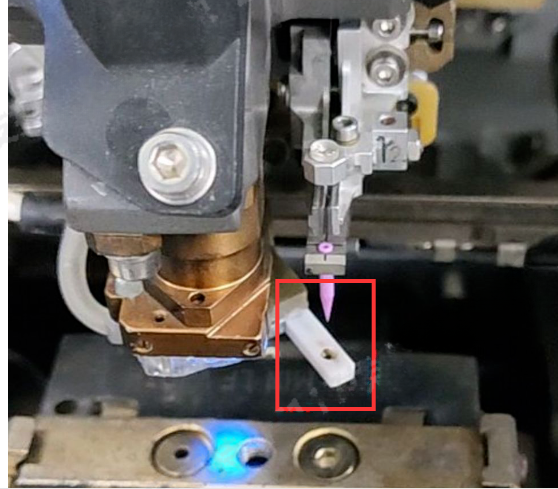

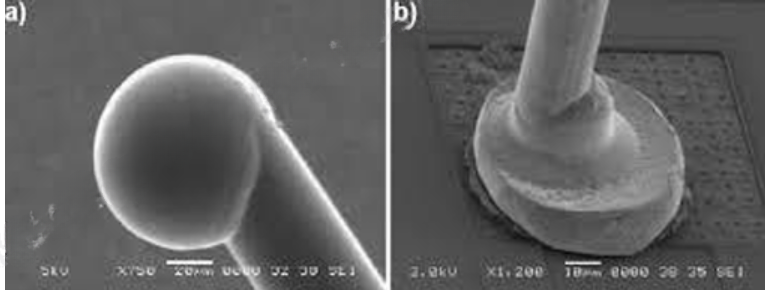

In copper wire bonding, inert gas is essential to block oxygen from the atmosphere and prevent oxidation of the Free Air Ball (FAB) during ball formation. Without proper shielding, oxidation can damage bonding quality and lead to reliability issues.

Oxygen content is a key factor in this process. If oxygen levels are too high, the FAB can deform and oxidize during melting. As the EFO (Electronic Flame-Off) current increases, the higher melting temperature of copper causes the surrounding gas to expand rapidly. If protective gas flow is too low, the FAB will not be fully covered by the inert atmosphere, leaving its surface exposed to oxygen and prone to oxidation.

Conclusion:

Proper control of protective gas flow is critical for copper wire bonding. A balanced flow prevents oxidation, avoids ball shape defects, and ensures stable, reliable bonds.

We are proud to participate in GOACON 2026 in Gujarat, showcasing our Ceramic Femoral Head and Liner...

READ FULLIn copper wire bonding, inert gas is essential to block oxygen from the atmosphere and prevent oxida...

READ FULL