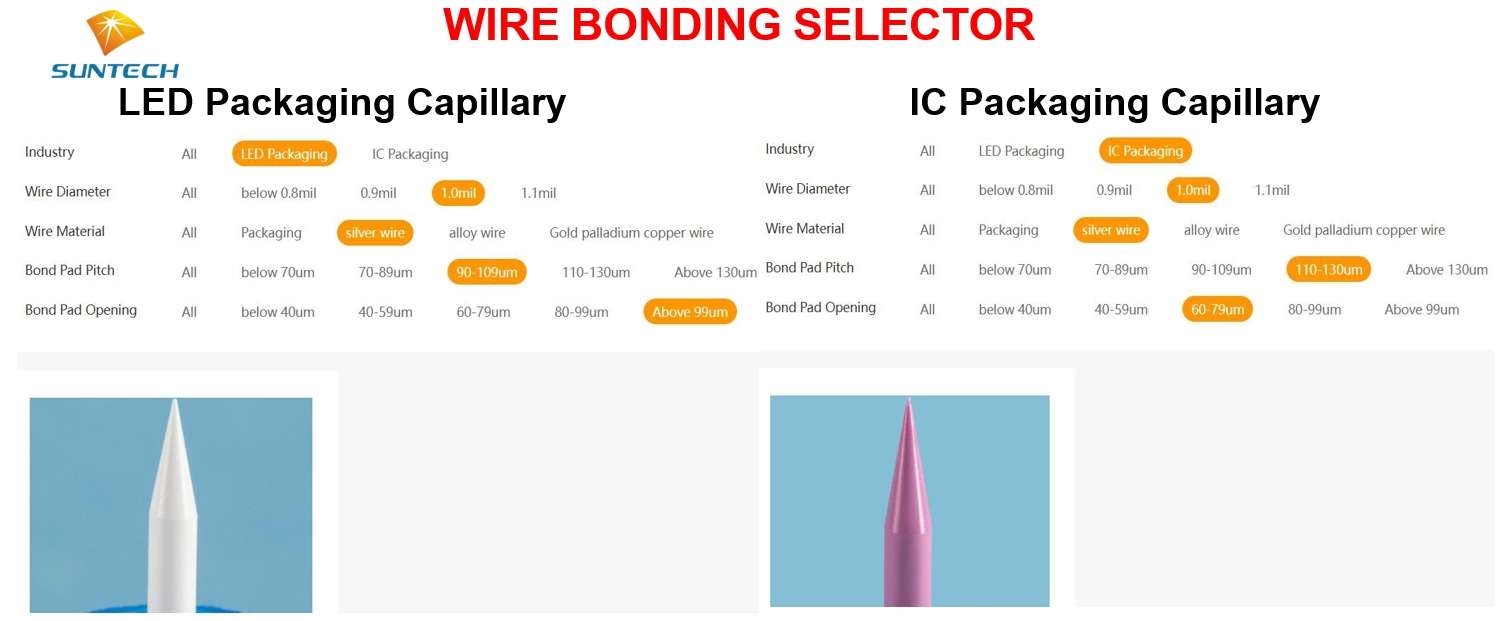

Precision ceramic capillaries are essential for achieving reliable wire bonding in semiconductor packaging, but LED and IC packaging applications require different specifications.

LED Ceramic Capillaries

✔Designed for thicker gold and copper wires used in high-power LEDs

✔Larger internal diameter and flat-head tip for smooth wire feeding and robust bonding

✔Superior thermal conductivity to efficiently dissipate heat during operation

IC Packaging Ceramic Capillaries

✔Engineered for fine-pitch bonding with ultra-fine wires (18–25 μm diameter)

✔Smaller, highly polished internal passage and sharper blade angle for micron-level precision.

✔Enhanced with advanced nano-coatings to reduce wear and improve bonding stability.

Both capillaries are crafted from durable zirconia ceramic and built to withstand high-speed, high-temperature bonding environments.

Whether your focus is on LED, photovoltaic, MEMS, or RF device manufacturing, our tailored ceramic capillaries provide the reliability and precision you need.

Discover which capillary suits your production goals—contact us for expert guidance and samples today!

We are proud to participate in GOACON 2026 in Gujarat, showcasing our Ceramic Femoral Head and Liner...

READ FULLIn copper wire bonding, inert gas is essential to block oxygen from the atmosphere and prevent oxida...

READ FULL