Material

High-purity aluminum oxide (Al₂O₃), silicon carbide (SiC), or silicon nitride (Si₃N₄). Advanced porous ceramic structure for uniform vacuum distribution.

Features

- The porosity is high: An important feature of porous ceramics is that they have more uniform and controllable pores. The pores are divided into open pores and closed pores. The open pores have the functions of filtering, absorbing, adsorbing, and eliminating echoes, while the closed pores are beneficial for blocking heat insulation, sound, and liquid and solid particles.

- High strength: The porous ceramic material is generally obtained by high-temperature calcination of metal oxide, silicon dioxide, silicon carbide, etc. These materials have high strength, and the boundary portion of the raw material particles melts and bonds during the calcination process, forming a high strength Ceramic.

- Physical and chemical properties are stable: Porous ceramic materials can withstand acid and alkali corrosion, can withstand high temperature and high pressure, have good clean state and will not cause secondary pollution. It is a green and environmentally friendly functional material.

- High filtration precision and good regeneration performance: The porous ceramic material used as a filter material has a narrow pore size distribution range and a high porosity and specific surface area, and the filter material is in full contact with the ceramic material, and suspended matter, colloids and microorganisms are blocked in the filtration. The surface of the media or the inside is well filtered. After a period of use, the porous ceramic filter material is backwashed with gas or liquid to restore the original filtration capacity.

Application

Semiconductor Industry – Wafer handling, dicing, and inspection

Flat Panel Display (FPD) Manufacturing – Holding glass panels during processing

Customization Options

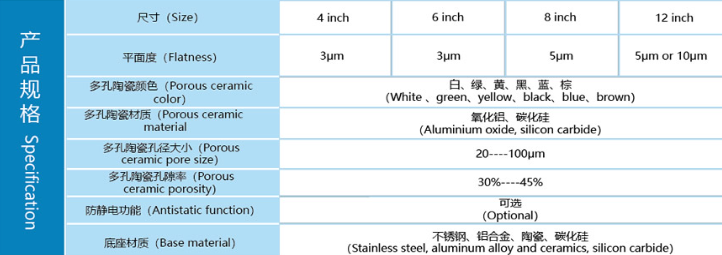

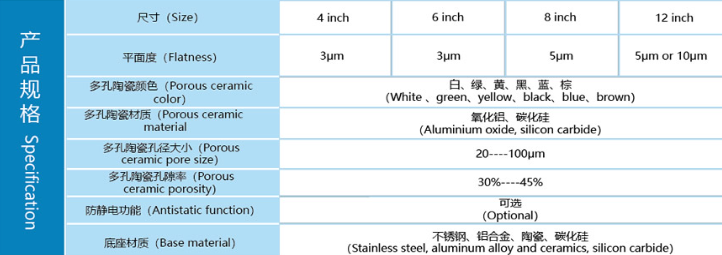

Size, shape, and porosity tailored to application needs.